@MasterAbbott

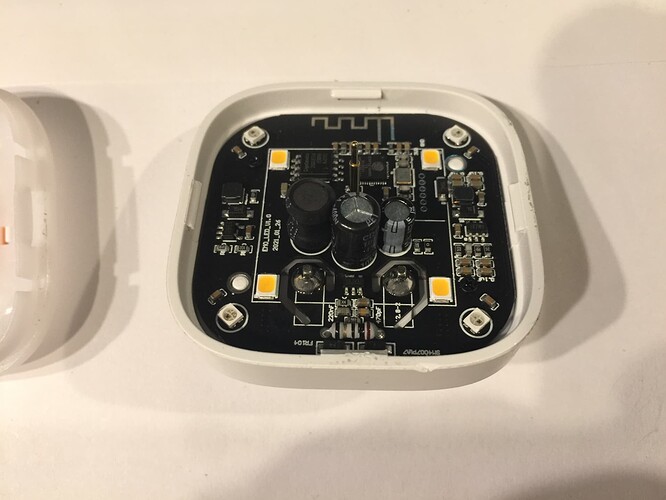

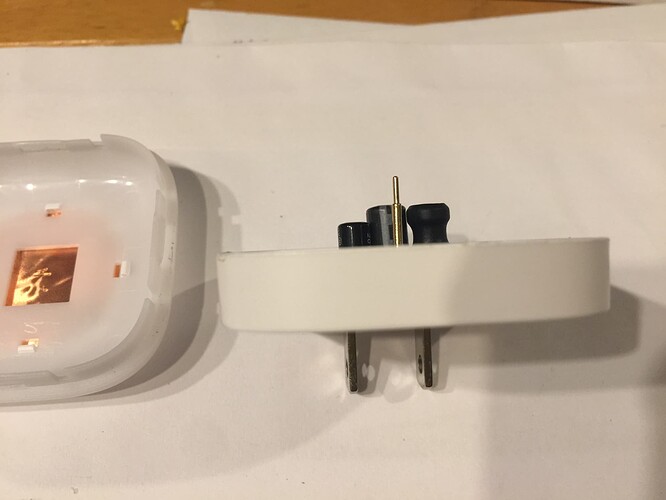

Nice find, whose video is this from? Now this is all making sense, it’s set up very similarly to his smart light. Those two pins are what are known as pogo pins, and are spring-loaded to maintain solid contact when they’re partially compressed. They’re used in ATE machines, Automated Test Equipment or “board of nails” type testers which verify multiple circuit board connections all at once. In this case they just used the pins to make an electrical connection from the circuit board contacts to the copper foil sheet on the plastic case, which is there to act as an antenna to detect the capacitance from the proximity of your hand (not pressure). You can look at the picture I attached of the inside of the smart light, they used a similar arrangement there to connect from the circuit board to the copper touch pad, except they only used one pogo pin in that case.

The flaw I see with this design is that bare copper oxidizes very easily over time. It will turn from it’s normal bright pink color when pure and darken to brown (like a penny) or even black as increasing amounts of copper oxide form on its surface. That copper oxide coating starts to act as an insulator as it builds up. On a circuit board the bare copper traces are normally protected with either a plating of tin metal which is much less prone to oxidation, or a coating of a plastic solder mask material. In those cases though it’s only performing a protective function.

Where maximum conductivity has to be maintained though (for example on the edge fingers of a circuit board) gold plating or sometimes palladium plating covers the copper since those metals do not oxidize. Silver is extremely conductive but it also oxidizes and forms sulfides very easily so it’s not normally left bare. Silver jewelry used to have the thin outer plating of rhodium to stop tarnishing before it got so terribly expensive (Around $26000/Toz). Even palladium costs more than gold these days, because all these exotic metals like platinum, palladium, and rhodium are used in catalytic converter‘s. That’s why thieves steal them off of cars. Even the tiny amounts coated onto the ceramic honeycomb inside a catalytic converter can be worth hundreds of dollars.

So the long and short of it is I can see what they were intending with the so-called “calibration procedure”. A bit of pressure on the case where they contact the copper foil might cause the tips of the pogo pins to shift position slightly and get into a more conductive spot. A much better plan going forward would be for a portion of the copper foil right near where the pins make contact to be plated with gold? That’s not as expensive as it sounds, gold plating for electronics these days is so extremely thin that it’s only a few Cents worth of gold. Even a tin plating would be better than bare copper though.

Another thing I noticed with the light is that the pogo pen there has a hemispherical shaped end on it, which is probably the worst shape it could be due to the small contact area. I can see why they did it though, since a sharper point might pierce the foil over time. The foil in the light is in a cutout area so is not backed by plastic like it is for the petting sensor. I can’t tell from your photos what the shape of the pogo pins for the petting sensor are? As you can see from my other photo though, those pogo pins are made with all kinds of different shapes which are capable of biting into a surface so they don’t move around or lose contact.

Edit: I’ve been out of touch with rhodium prices, it’s down to only about $14,800.00 per troy ounce now. The Internet being what it is I figured someone would correct me if I didn’t do it myself.